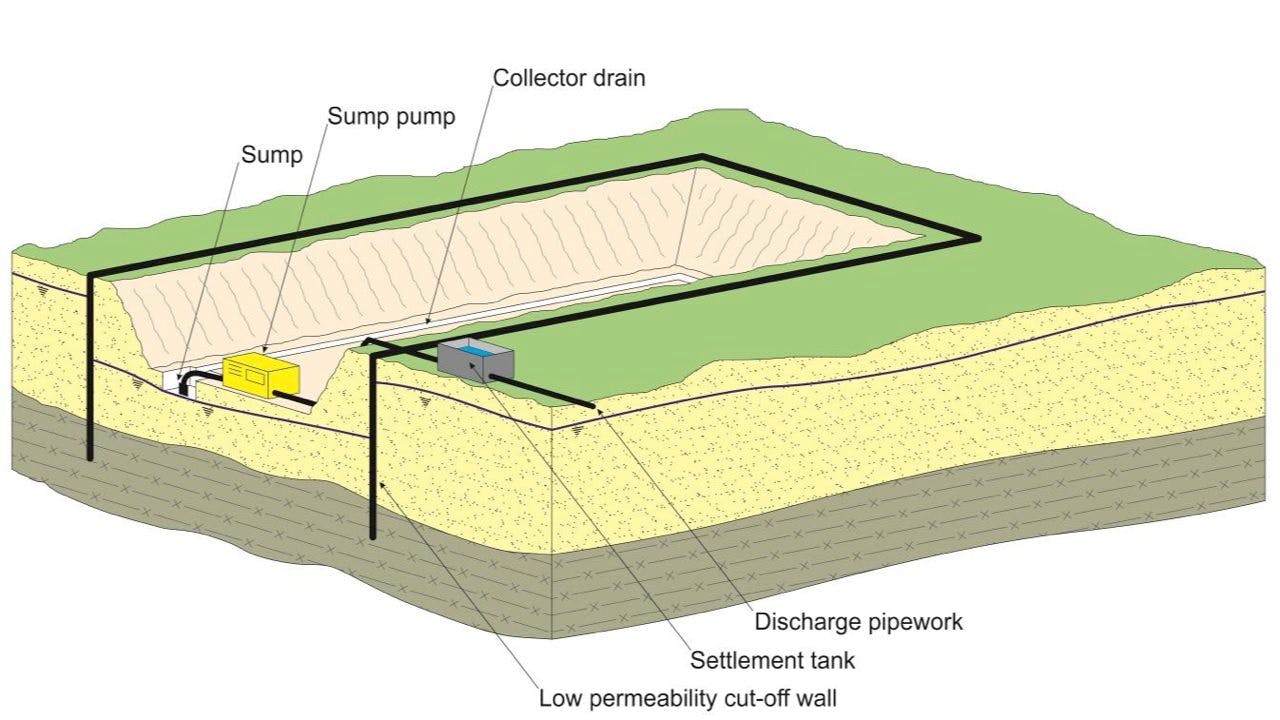

Dewatering is often required to allow excavations to be made in dry and stable conditions below groundwater level for construction projects or open pit mines. Dewatering systems typically involve pumping from an array of wells or sumps to lower groundwater levels, and may also involve low permeability cut-off walls to exclude groundwater.

On any given site there may be several possible configurations of dewatering system in terms of number and location of wells, cut-off walls, pump capacity and other system parameters that will achieve the required lowering of groundwater levels within the excavation. With the widespread availability of computing power in everyday geotechnical engineering it has become fairly straightforward to analyse multiple groundwater flow scenarios (either as spreadsheet-based analytical models or numerical groundwater models) and apply these scenarios to dewatering design.

It is a logical step to go from analysing multiple scenarios to deriving an ‘optimal’ dewatering design, typically based on optimising the number of wells or the pumped flow rate. Numerical solutions to optimal dewatering design were tried as early as the 1970s and since then have developed along with emerging numerical decision making tools of their time, such as expert systems multi-attribute decision analysis and artificial neural networks, amongst others.

Previous studies have often taken a fundamentally mathematical approach to optimisation, in many cases in an attempt to provide better reliability or consistency in dewatering design, in part by reducing the role of ‘expert judgment’. The current blog takes a different approach to look at the challenges and pitfalls of optimisation of dewatering systems and will discuss non-numerical optimisation strategies.

WHAT IS DEWATERING?

Dewatering (also known as groundwater control) is often required to allow excavations to be made in dry and stable conditions below groundwater level. There are two principal groups of groundwater control technologies as listed below.

Pumping methods for groundwater control:

Exclusion methods for groundwater control:

Dewatering can involve pumping methods where groundwater is pumped from an array of wells or sumps to temporarily lower groundwater levels.

Groundwater control by pumping

Alternatively, exclusion methods can use low permeability cut-off walls to exclude groundwater from the excavation. Pumping and exclusion methods may be used in combination.

Groundwater control by exclusion

WHY OPTIMISE?

Groundwater control is one of first geotechnical processes required on a project, and is often the first that must be proven to allow work to proceed. If groundwater control does not work effectively, or causes delays, these problems will occur at the start of the project, and can critically affect later stages of construction.

In contrast to many other forms of geotechnical processes, dewatering design is not covered in detail by geotechnical design codes. For example the dewatering section in Eurocode 7 is only one page long, and there is no corresponding execution standard for dewatering. Dewatering guidance documents do exist in the UK, United States and in Qatar and Abu Dhabi in the Middle East, but tend not to be prescriptive and are typically in the form of ‘toolkits’ of design methods and construction techniques. Therefore at the start of a project designer can be faced with a bewildering arrangement of design and implementation options, and a rational optimisation approach can look attractive.

METHODS OF OPTIMISATION

There are four main approaches to dewatering design and optimisation:

Empirical optimisation

This is a design approach based largely on experience, local knowledge and ‘rules of thumb’. Optimisation by empirical methods has been successfully used on many simple projects. A simple project can be defined as one where: the hydrogeological conditions are well defined and relatively straightforward; where the excavation is relatively small and shallow; and, where environmental impacts are not a key concern. Examples might include shallow basements, pipeline projects, sewers, etc.

When geotechnical engineers become involved in dewatering design, the use of empirical design is sometimes viewed as being less rigorous compared to numerical or analytical methods. However, there is a huge track record of empirical methods providing successful dewatering designs. One of the reasons why this is the case is that, provided the correct groundwater control method is selected, a given dewatering technology can often successfully deal with modest variations in ground conditions. However, there are limits (e.g. in terms of hydraulic conductivity) for each dewatering method beyond which it is not effective. It is essential to select the correct dewatering technology for a project.

Analytical optimisation

The analytical approach uses hydrogeological equations (as might be found in a textbook) to estimate pumped flow rates and drawdowns. It is typically suited to relatively simple hydrogeological conditions with few complex boundaries (rivers, faults, other abstractions). Each set of analytical equations is only applicable to a relatively narrow range of hydrogeological boundary conditions, and gross errors can result if used in the wrong conditions.

Numerical optimisation

This involves the use of 2 or 3 dimensional numerical groundwater flow models. Numerical modeling is used far more in dewatering design and optimisation than it was 10 years ago. This popularity is because the necessary investments in software, hardware and training have reduced dramatically, and also because modern software can easily demonstrate results visually for non-technical project clients. Numerical modelling offers the flexibility to take into account known or inferred variations in the aquifer within the range of influence. This might include assessing the effects of a nearby river, another dewatering project, or a natural barrier in the aquifer.

Both numerical and analytical approaches need to be applied based on a ‘hydrogeological conceptual model’ that captures the important features of the groundwater system at the site and its environs. The conceptual model will normally be developed directly from the site investigation data, including a hydrogeological desk study. If the conceptual model is inaccurate or incomplete, the results of any subsequent modeling or analysis are likely to be erroneous.

Observational optimisation

This approach uses construction observations to design and refine the dewatering system. Construction observations (for example pumped flow rates and groundwater drawdown levels) are used to guide optimisation of the system as part of a deliberate process of design, construction control, monitoring and review. Occasionally, dewatering systems are not effective when initially installed, and a ‘troubleshooting’ investigation is needed. This approach takes place during construction, and so has access to field data (e.g. dewatering well logs, pumped flow rates, drawdown water levels) that were not available to the original designer. These data need to be reviewed to identify whether the lack of performance is related to: ‘unexpected ground conditions’ (i.e. ground conditions different to the assumed conceptual model); operational problems with the current system (e.g. existing pumps and wells not delivering their design capacity); or the fundamental issue of the wrong dewatering technology or approach being used. The objective of troubleshooting is to develop a plan of action, to develop an effective dewatering system at the site, suitable for current conditions

POTENTIAL PROBLEMS WITH OPTIMISATION

A wide range of problems can occur when dewatering systems are optimised, as outlined below.

Lack of clarity in objectives of optimisation: A fundamental problem with dewatering optimisation is lack of clarity in the objectives of optimisation, and failure to recognise that optimising in one aspect may require compromises in other aspects.

Data quality and quantity: The data from site investigation and previous projects are the foundation of the conceptual hydrogeological model and all subsequent calculations, modelling or analysis and dewatering system design. If these data are inadequate in quality or quantity everything after this step will be of limited value. No modelling effort can correct false or poorly determined parameters. A valid part of dewatering optimisation may ultimately be to recommend additional ground investigation to plug any identified data gaps, and/or to recommend that the dewatering system be implemented by the observational method to provide flexibility against variations in ground conditions.

Errors in conceptual model: Getting the conceptual hydrogeological model correct is fundamental to the design and optimisation of dewatering systems. Many significant dewatering problems can ultimately be traced back to an inappropriate conceptual model that either leads the designer down the wrong design avenue, or causes the designer to ignore a design condition that is, in fact, important.

Inappropriate dewatering method: Each type of pumped dewatering method is applicable to a finite range of ground conditions. If an unsuitable dewatering method is selected at the outset of design (e.g. if ejector wells are used in a high permeability soil) then even extensive and detailed optimisation measures are likely to be futile.

POSSIBLE PRIORITIES FOR OPTIMISATION

Traditionally, the main priority for dewatering optimisation is to reduce installation costs or occasionally to meet regulatory requirements, such as when a limit has been set on the maximum permitted discharge rate. Increasingly, there is also a focus on developing effective dewatering systems that have minimal environmental impacts (such as ground settlement). However, there are several different strategies that can be adopted for optimisation, as outlined below.

Lowest pumping rate: Risk that system will not have sufficient spare capacity to handle modest increases in flow rate above design values.

Lowest energy usage: Will tend to favour lowest pumping rate solutions, with the same risks. May involve use of smaller pumps for steady state pumping, once initial drawdown has been achieved.

Minimal impacts: May favour groundwater exclusion solutions that use low permeability cut-off walls to avoid or minimise pumping.

Minimal capital cost: Will tend to favour lowest pumping rate solutions, with the same risks.

Minimal operating cost: Will tend to favour lowest pumping rate solutions, with the same risks.

Shortest dewatering period: May be appropriate for emergency dewatering systems to recover a project after a failure or inundation, or for projects where the dewatering costs are small relative to project weekly on-costs.

Maximum certainty of outcome: May be appropriate for projects where programme certainty is a key factor, and the dewatering must be fully effective without time consuming modifications.

CONCLUSION

It is important to realise that there is no perfect optimisation method that will address all the possible priorities for a dewatering system. In reality, different aspects of optimisation may conflict, and there will need to be trade offs between different priorities of design. The required conditions for effective optimisation of dewatering systems include: clarity of the objectives of optimisation; adequate site investigation data; development of a valid hydrogeological conceptual model; and, selection of the most appropriate dewatering method at the earliest possible stage of optimisation.

This article is based on a paper presented at the XVI European Conference on Soil Mechanics and Foundation Engineering in Edinburgh, Scotland in September 2015. The paper was co-authored with Erik Loots of Loots Groundwater International

A PDF summary of the paper can be downloaded here

© Martin Preene. Web Design by Statement.